Good Lumens vs Bad Lumens

November 24, 2015

In the lighting world, specification sheets tend to just list fixture (or lamp) lumens. In many cases, as designers, that is all the info we need.

But sometimes we need a little more info about how these fixtures distribute light. Is a fixture a Wide Flood, Narrow Flood, Spot, Volumetric, Parabolic…or something else?

In other cases still, we need more.

One of those cases is with exterior lighting.

Exterior Distribution Types

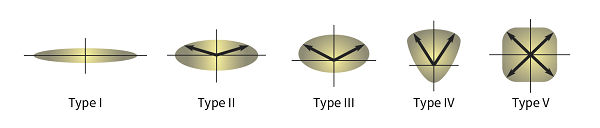

Shown above are the five main distribution types for exterior area lighting. Each type has certain applications that it is best suited for.

Shown above are the five main distribution types for exterior area lighting. Each type has certain applications that it is best suited for.

Type I – Used for pathways, narrow roadways and at the front row of car dealerships

Type II - Also often used on roadways, when you need light distributed very far to the sides, but not very far forward

Type III – Provides not as much distribution to the sides, but more forward distribution

Type IV - Sometimes just called “Forward Throw.” It does just that, it distributes light forward from the pole. Most suitable along the perimeter of sites

Type V – Can be round or square. It distributes light relatively evenly in all direction from the poles. Most suitable in the center of larger sites

Up until a few years ago most site lighting was done with High-Intensity Discharge (HID) lamps. These were big lamps that utilized large reflectors to get the light distributed in the proper directions and intensities. While most of what is still out there is still HID, new construction, and more recently retrofitting is driving the shift toward LED lighting.

Shrinking Optics

The change to small LED light sources allowed us to shrink the optics. The optics that were once done on the macro level, with large reflectors, are now done on the micro level with either much smaller metal reflectors, or small optical refractors.

These changes created much more optically efficient light fixtures, which is one of the major reasons, along with source efficacy and lumen depreciation, for why LED outdoor lighting requires far less wattage than their HID counterparts.

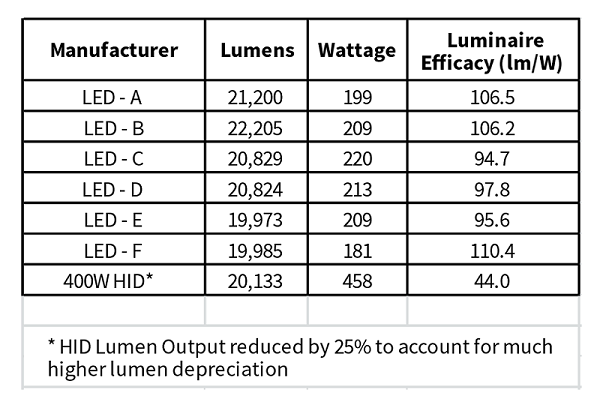

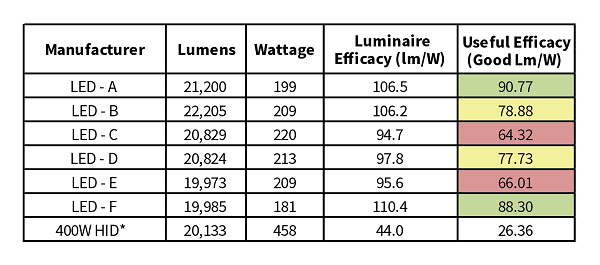

A simple look at design lumen output (chart below) shows how six LED fixtures stack up against a typical 400W Metal Halide area light. These are the numbers that we would expect to see on a specification sheet, from these manufacturers. Our LED fixtures are all producing roughly the same fixture lumens at less than half the wattage of the HID, which gives us LED luminaire efficacies (lm/W) of 2-2.5x the HID fixture.

How LED Optics Make a Difference

How LED Optics Make a Difference

It’s a well-established fact in the lighting industry that LED outdoor area lights have a much higher luminaire efficacy than their HID counterparts, but how do these LED fixtures compare against each other?

Fixture lumens are directionally agnostic. They could be directed up, down, back, front, left, or right and their intensities in those directions could be drastically different.

As a lighting designer I care about where those lumens are going, not how many total lumens there are. As you can see in the chart above, all of our LED fixtures have roughly the same total lumen output and efficacy (within 10-15%).

But where are those lumens going?

I was recently asked to do a lighting analysis for a Small Box retailer. These sites are typically 2-3 acres in size, with lots of parking. Lighting for their parking lots was typically just around the perimeter of the site, aiming inward. For this project we found ourselves using at least 80% Type IV distribution LED fixtures, so that’s where my analysis focused.

My task was to determine which manufacturer had the best LED fixture for this retailer. That’s a complicated task, since “best” can often times be subjective, and in the LED world, ever-changing. So I started by looking at the attribute that was least likely to change and wasn’t subjective. Optics.

I looked at five different locations for this retailer, analyzed six different major lighting manufacturers and targeted Type IV fixtures with outputs in the 20,000 lm range.

I wasn’t sure what I was going to discover.

I was prepared to find that everyone’s Type IV optics were about the same, but instead I found something much more interesting: one of those six fixtures significantly outperformed the other five.

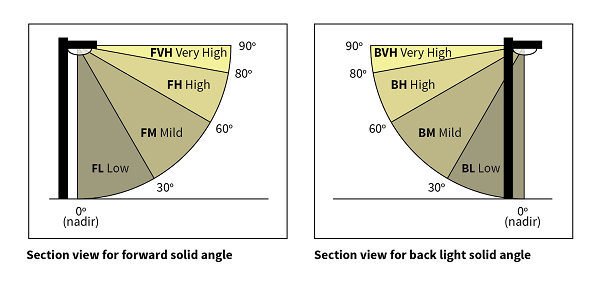

Digging into the Luminaire Classification System (LCS) data, I found that the high performing fixture had a higher percentage of forward throw light than the poorly performing fixtures.

Given that these fixtures are on the perimeter of sites, it makes sense that the more forward light a fixture produces, the better that fixture will perform against its competitors. If we are considering the forward throw lumens to be “Good Lumens,” then we need to consider the back light lumens to be “Bad Lumens.”

Good Lumens

Good Lumens

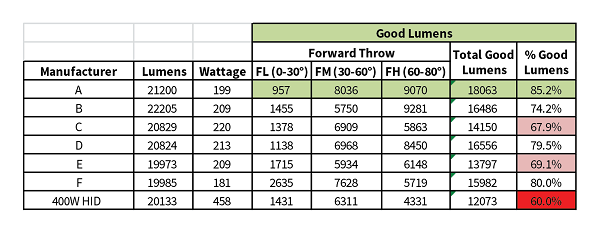

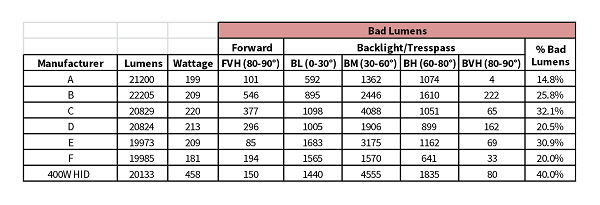

In the chart below I dig deeper into the optical performance of each of the six LED fixtures I analyzed, as well as the example 400W HID fixture. Any lumens directed forward and between 0° and 80° altitude are considered Good Lumens. As you can see, manufacturer A was our highest performing fixture with 85.2% of its total fixture lumens directed in desirable directions. Manufacturers B, D, and F were in the second, mid-tier group. Manufacturers C and E were the worst performing, not actually performing too much better, optically, than our example 400W HID.

So what do these Good Lumens do for us? There are two answers here:

- Using the higher performing fixtures could produce higher average foot-candle levels

- Using the high performing fixtures could allow us to reduce the wattage of the fixture while maintaining the same average foot-candle levels

For this project, the customer had a hard average foot-candle spec of 3.0fc, so designing with our high-performing fixtures allowed us to use a lower wattage fixture and still achieve the desired maintained average of 3.0 foot-candles

Bad Lumens…wasted or detrimental?

My analysis considered Bad Lumens to just be wasted, but there are scenarios where these lumens can actually be detrimental to the design. Depending on the site’s location and the local jurisdiction, any back light Bad Lumens could cause you to need to add shielding to prevent too much light from spilling off the property.

Additionally, the forward lumens at high angles (FVH 80-90°) could be the source of glare issues and are also considered Bad Lumens. Bad Lumens can be wasted lumens or harmful lumens, but either way they aren’t Good Lumens. Below are the corresponding Bad Lumens for the same example fixtures.

It can’t ALL be about optics though. The fixture needs to produce a high percentage of good lumens without sacrificing overall luminaire efficacy.

Wattage still matters. This is where our high-performing optical fixture (Manufacturer A) continues to stand out from the crowd. The high optical efficiency combined with the high luminaire efficacy leads to a high “Useful Efficacy.” This metric is simply (Total Good Lumens) / (Fixture Wattage). We can see three tiers of products when we look at Useful Efficacy.

Tier 1 (Mfgs A & F) – Useful Efficacy ~ 90lm/W - Fixture A continues to perform well, but Fixture F joins it in the top tier because it has a decent percentage of Good Lumens and a high overall Fixture Efficacy.

Tier 2 (Mfgs B & D) – Useful Efficacy near 80lm/W – Fixtures B and D combine middle-of-the-road optical efficiency and luminaire efficacy to come out with a decent Useful Efficacy. If these fixtures were significantly cheaper than the Tier 1 fixtures, I could argue for using them.

Tier 3 (Mfgs C & E) – Useful Efficacy of around 65lm/W – Simply put, fixtures C and E just don’t perform very well. While looking at their cut sheets might not point us in that direction, digging a little deeper shows that these fixtures perform about 30% worse that the Tier 1 fixtures.

Maximizing Good Lumens Leads to Energy Savings

At the end of the day, using manufacturer A allowed me to drop an entire wattage class (14,570 Good Lumens at 156W). Fixture A’s high Useful Efficacy meant it was able to maintain the same light levels as competitors that are around 210W. Rolled out over the entire store portfolio, using this fixture would save the end user about $8,000,000 in energy costs over 10 years.

As we know, with LEDs, fixture wattages are only static for one LED generation. A 400W Metal Halide lamp has drawn 458W for decades, but LED fixture wattages change almost constantly. In fact, in the time I was doing this analysis Manufacturer B informed me of a new generation of their fixture and I had to go back and adjust their data. Constantly staying on top of what is available is very important and it’s a large part of my job.

The Benefits of Digging

My general takeaway from this detailed analysis is that just looking at specification sheets can be deceptive.

If I would have compared the specs for Manufacturer A and Manufacturer E, they would have looked pretty similar. Sure Manufacturer A has slightly better numbers. While A and E likely would have been considered equals in a Request For Proposal (RFP) situation, digging deeper has shown us that they are far from being the same, which could have a large impact on the financial success of the project.

Tony Johnson is Energy Management Collaborative's Solution Engineer. In this role he combines his background in lighting + controls design and solid state light fixture design with his expertise in energy savings to evaluate emerging technologies for EMC customers.