Scaffolding: Stay Safe with Proper Training and Use

November 4, 2024

Scaffolding: Stay safe with proper training and use

In the past three months these grim headlines related to scaffolding safety made the news:

Construction worker dies in fall from building in downtown Boston

Daring rescue saves two as scaffold hangs off Milwaukee courthouse

Worker dies after electrocution, fall from scaffolding in Philadelphia, police say

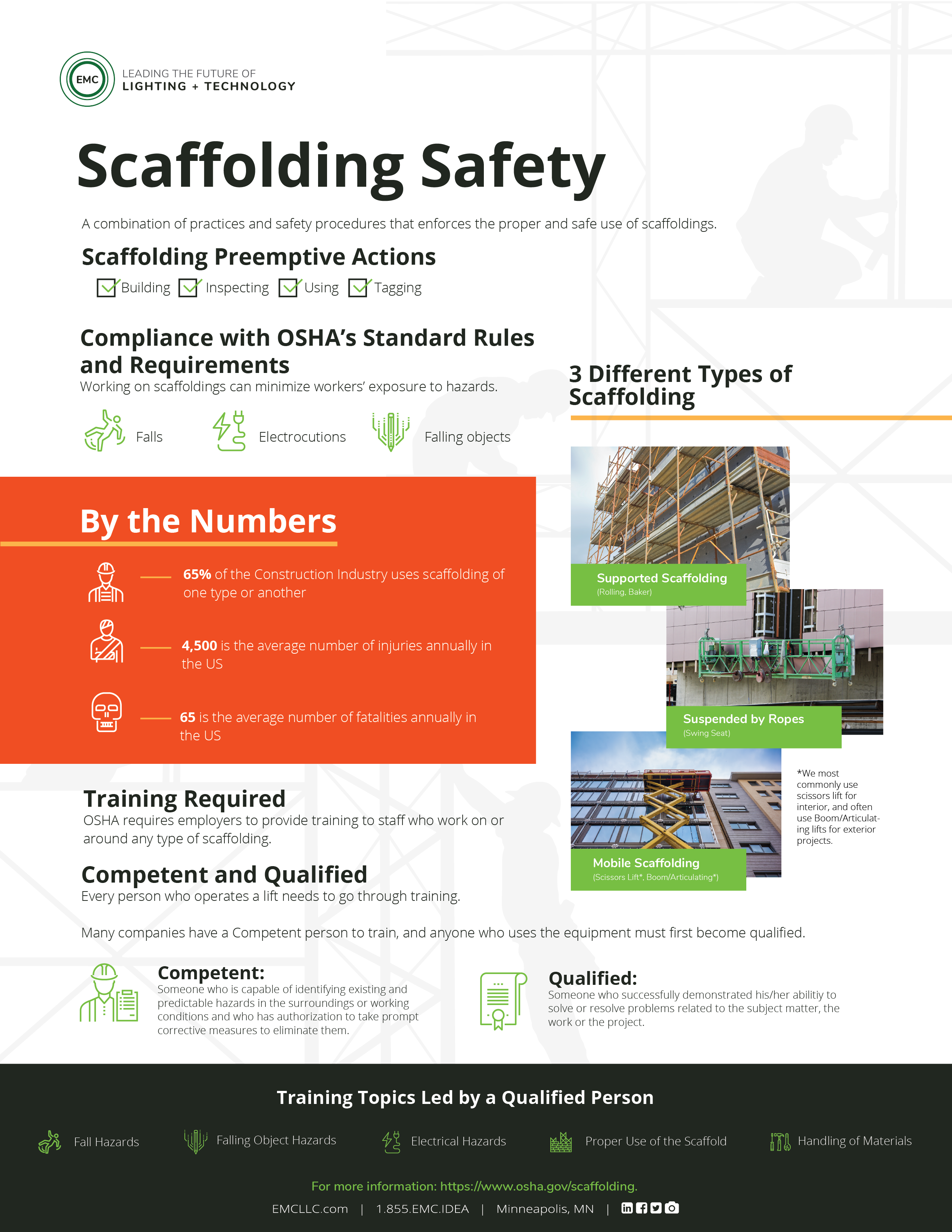

Sadly, these incidents reflect sobering statistics. With 65% of the U.S. construction industry using scaffolding of one type or another, the U.S. Department of Labor Statistics reports an average of 4,500 scaffolding-related injuries and 65 deaths each year.

What can be done to avoid scaffolding accidents? Keep safety top of mind with a combination of practices and procedures that enforce the proper and safe use of scaffolding. This includes preemptive actions in building, inspecting, using and safety tagging scaffolding.

OSHA Compliance

Following Ladders, Scaffolding is the fourth most-cited Occupational Safety and Health Administration (OSHA) violation in 2023. Complying with OSHA standard rules and requirements for working on scaffolding can help minimize workers’ exposure to hazards. OSHA requires employers to provide training on topics such as fall hazards, falling object hazards, electrical hazards, proper use of the scaffolding and handling of materials to staff who work on or around any type of scaffolding.

OSHA requires companies to designate competent and qualified personnel to identify and correct workplace hazards. A competent person can identify hazards and has the authority to correct them. They have demonstrated their ability to identify hazards in the workplace, including unsanitary or dangerous conditions.

A qualified person can identify hazards, but they also have additional training, experience or instruction that allows them to perform tasks that a competent person cannot. Many companies have a competent person to train, and anyone who uses the equipment must first become qualified. Every person who operates a lift needs to go through training.

Safety for Different Types of Scaffolding

Scaffolding comes in three types:

- Supported Scaffolding (Rolling, Baker)

- Suspended by Ropes (Swing Seat)

- Mobile Scaffolding (Scissors Lifts, Articulating/Boom)

In the lighting industry we most commonly use Scissors Lifts for interiors and Articulating/Boom or Lifts for exterior projects.

Because Articulating/Boom and Scissors Lifts are so common in our projects, it is easy to put aside simple safety requirements to use the equipment. Just getting on the lift and showing a new person how to operate them is NOT the right, safe or legal way to train.

Equipment Safety

In general, a scaffold should be checked and inspected before being used for the first time, and then at regular intervals during its use. The specific frequency depends on factors such as the type of scaffolding used, the site condition and whether it is exposed to extreme conditions that may affect its structural integrity.

Basic scaffolding safety practices include the following Do’s and Don’ts for all types of scaffolding used:

Scaffolding Safety Do’s

- Inspect the scaffold using a checklist or mobile inspection app before the work shift.

- Provide proper training.

- Have a toolbox talk before beginning work.

- Wear appropriate PPE.

- Always check inspection tags.

- Know the weight capacity of the scaffold.

- Have a handhold above the scaffold platform.

- Level the scaffold after each move. Do not extend adjusting leg screws more than 12 inches.

- Use your safety belts and lanyards when working on scaffolding at a height of 10 feet or more above ground level. Attach the lanyard to a secure member of the scaffold.

- Safely use the ladder when climbing the cross braces for access to the scaffold.

- Keep both feet on the decking.

- Stay off the scaffold during loading or unloading.

- Follow the manufacturer’s instructions when erecting the scaffold, under the direct supervision of a competent person.

- Be mindful of coworkers working above and below you at all times, as well as others working on the scaffold.

- Always use netting to catch anything that falls.

Scaffolding Safety Don’ts

- Don’t leave anything on the scaffold at the end of your shift.

- Don’t overload the scaffold.

- Don’t use unstable objects to support scaffolds or increase your work height or planks.

- Don’t use the scaffold if it appears to be damaged in any way.

- Don’t walk on scaffold planking covered in ice, snow or mud.

- Don’t use a scaffold during adverse weather conditions.

- Don’t lean out or overreach outside the guardrails.

- Don’t rock the scaffold.

- Don’t throw anything “overboard” unless a spotter is available.

- Don’t move a mobile scaffold if anyone is on it.

With scaffolding there is more than meets the eye when it comes to staying safe. Each type of scaffolding requires different training, knowledge and measures to use safely and properly. Be aware of and respect the equipment you use daily. It is paramount to going home safely at the end of the day/job and avoiding becoming the next tragic headline.

Gary Giesen, CLMC CALT, is Principal Master Electrician and Field Quality Lead for EMC. In addition to a passion for Safety, Gary brings more than 40 years of Safety/EMS experience, with more than 20 years as an OSHA 10/30 Instructor, and almost 30 years as an EMT and CPR instructor.